The Future of Fibre Optics: Why the Optical Fibre Diameter Analyser is Key to Advancements

The Future of Fibre Optics: Why the Optical Fibre Diameter Analyser is Key to Advancements

Blog Article

How an Optical Fibre Diameter Analyser Boosts Quality Assurance in Fibre Production

The integration of an Optical Fibre Diameter Analyser into Fibre production processes represents a substantial development in high quality control techniques. By supplying real-time, precise dimensions of Fibre diameters, this technology deals with the important need for consistency in manufacturing criteria.

Importance of Fibre Diameter Dimension

Accurate measurement of Fibre Diameter is crucial in the area of optical Fibre innovation, as it directly influences the performance and integrity of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capability, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter makes certain that the optical buildings are kept within defined tolerances, which is vital for optimum signal honesty.

Variations in Fibre Diameter can result in increased losses because of spreading and modal dispersion, affecting the high quality of information transmission. In high-speed communication systems, such discrepancies can cause substantial deterioration of signal high quality, resulting in information errors and lowered efficiency. Furthermore, consistent Fibre Diameter is crucial for compatibility with ports and splicing innovations, which are integral components of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily count on accurate Diameter dimensions to make sure conformity with market requirements. By carrying out robust dimension strategies, makers can enhance item reliability, decrease waste, and boost general system performance. Therefore, the significance of Fibre Diameter measurement can not be overemphasized, as it acts as a foundation in the innovation of optical Fibre innovation and its applications in modern-day communication networks.

Just How the Analyser Works

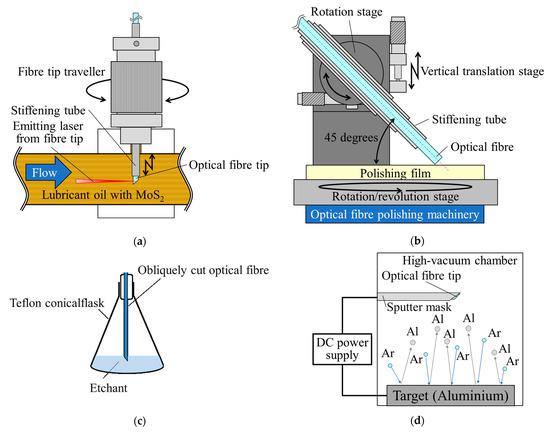

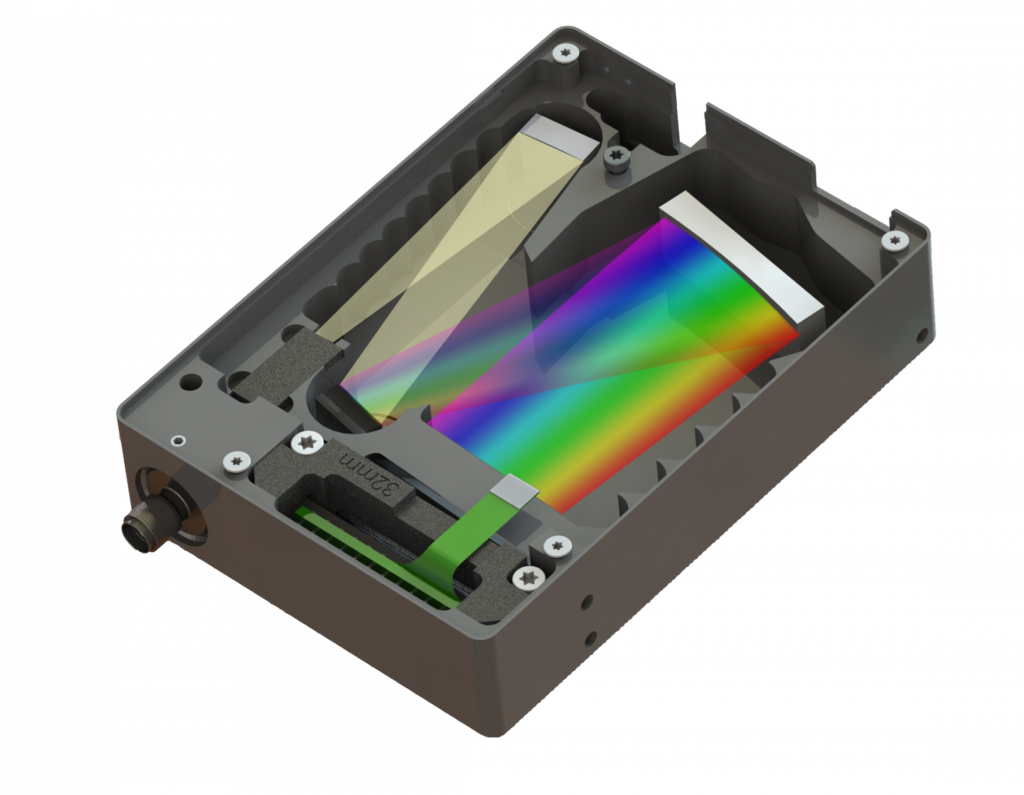

The reliable dimension of Fibre Diameter depends on innovative analytical methods that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser innovation and progressed photo handling algorithms to accurately assess the Diameter of fibers as they are generated

Originally, a laser beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this darkness utilizing high-resolution electronic cameras positioned strategically along the production line. The caught pictures are after that refined in real-time to figure out the Fibre's Diameter with phenomenal accuracy.

The system utilizes sophisticated algorithms that account for various elements, including variations in light intensity and environmental problems, to boost dimension integrity. It can detect minute changes in Diameter, such as variations that could take place throughout the manufacturing process.

Furthermore, the analyser is capable of dealing with multiple fibers all at once, boosting throughput without jeopardizing accuracy. By giving rapid comments on the Diameter, the Optical Fibre Diameter Analyser plays an important role in keeping rigid high quality control standards, making certain that the last product fulfills market specs and consumer demands.

Advantages of Real-Time Tracking

While traditional approaches of keeping an eye on Fibre Diameter frequently entail lengthy post-production checks, real-time tracking considerably boosts the effectiveness and top quality of optical Fibre production. optical fibre diameter analyser. This proactive strategy allows suppliers to identify inconsistencies in Fibre Diameter as they occur, instead of waiting until manufacturing is complete to evaluate top quality

By continuously gauging the Diameter during manufacturing, makers can make certain that the fibres fulfill strict specs, leading to minimized irregularity and improved uniformity. Real-time surveillance also allows prompt corrective actions to be taken, lessening waste and protecting against defective fibers from getting in the supply chain.

Furthermore, this innovation assists in boosted data collection and analysis, offering understandings right into manufacturing patterns and potential areas for enhancement. Such data-driven decision-making encourages suppliers to optimize processes and maintain high requirements of high quality control.

Additionally, real-time surveillance cultivates a society of continual improvement within the production environment. Employees are much more engaged when they can see the effect of their work in real-time, resulting in increased accountability and a commitment to excellence. Overall, the implementation of real-time monitoring systems in optical Fibre production converts to premium item top quality and boosted client satisfaction.

Impact on Production Performance

Applying optical Fibre Diameter analysers considerably enhances production performance by simplifying the production procedure. These tools promote continual tracking of Fibre Diameter, enabling producers to spot discrepancies in real-time. By identifying incongruities immediately, manufacturing lines can be readjusted swiftly, reducing click to read more downtime and reducing the chance of generating faulty items.

Moreover, the combination of these analysers right into the production process makes it possible for far better resource allocation. With exact Diameter dimensions, operators can maximize material use, guaranteeing that sources are not squandered on mistaken fibres. This accuracy also adds to less junk and rework, inevitably lowering manufacturing expenses.

The automation provided by optical Fibre Diameter analysers decreases dependence on manual assessments, which are susceptible and often lengthy to human error. Because of this, staff members can more helpful hints focus on more critical tasks, improving total productivity.

Additionally, the information generated from these analysers can notify procedure improvements and help with far better decision-making. By analyzing trends in Fibre Diameter variants, manufacturers can execute positive actions to boost manufacturing strategies and maintain consistent high quality. In recap, optical Fibre Diameter analysers play a critical role in increasing manufacturing efficiency, causing greater top quality result and increased success.

Study and Success Stories

Throughout different markets, study highlight the transformative influence of optical Fibre Diameter analysers on manufacturing procedures. One noticeable instance is a leading telecoms firm that encountered obstacles with irregular Fibre sizes, resulting in enhanced being rejected rates. By integrating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre dimensions, resulting in a 30% reduction in defects and considerable price savings.

Moreover, a research establishment concentrating on innovative materials used optical you can try here Fibre Diameter analysers to improve their experimental processes. The analyser's ability to provide in-depth understandings into Fibre uniformity allowed the growth of innovative materials with better performance attributes.

These success tales emphasize the important duty of optical Fibre Diameter analysers in improving top quality control, improving production effectiveness, and driving innovation across diverse markets.

Verdict

In verdict, the Optical Fibre Diameter Analyser plays a critical role in enhancing quality control within Fibre manufacturing. As shown with various case researches, the analyser confirms essential for accomplishing exceptional product quality in Fibre manufacturing.

The execution of optical Fibre Diameter analysers permitted for strict top quality control, making certain that the produced fibres satisfied exacting sector requirements.In verdict, the Optical Fibre Diameter Analyser plays a critical duty in enhancing high quality control within Fibre production.

Report this page